RF Microneedle Pro | Medical-grade RF microneedle intelligent manufacturing solution

Hard-core advantages of industry and trade integration

1.Vertical integration reduces costs by 30%: self-developed RF chips + fully automatic microneedle packaging line (cost is 25% lower than peers)

2.Lightning delivery in 10 days: Industrial 4.0 production line has a monthly production capacity of 60,000 units, supporting 72-hour functional prototype proofing (including 3D structure verification)

3.Military-grade quality control: 68 testing processes, passed 20,000 puncture tests (3 times more than FDA standards) + IPX7

waterproof certification

Flexible production system

1.72-hour rapid prototyping (including 3D functional prototype + packaging design)

2.Monthly base production capacity of 50,000 units, which can be expanded to 80,000 units during peak season

Full-link intelligent manufacturing system

1.10,000㎡ 100,000-level cleanroom (22 German Kuka robot production lines)

2.98% autonomy rate of core components (RF generator/titanium alloy microneedle/biosensor)

3.Shared the world's largest beauty equipment mold library (3,000+ sets of molds, new product development costs reduced by 40%)

Customization capability dimension

Hardware: supports laser engraving/vacuum plating/IMD color printing/antibacterial coating

Software: Open SDK interface, can be implanted with customer AI skin algorithm

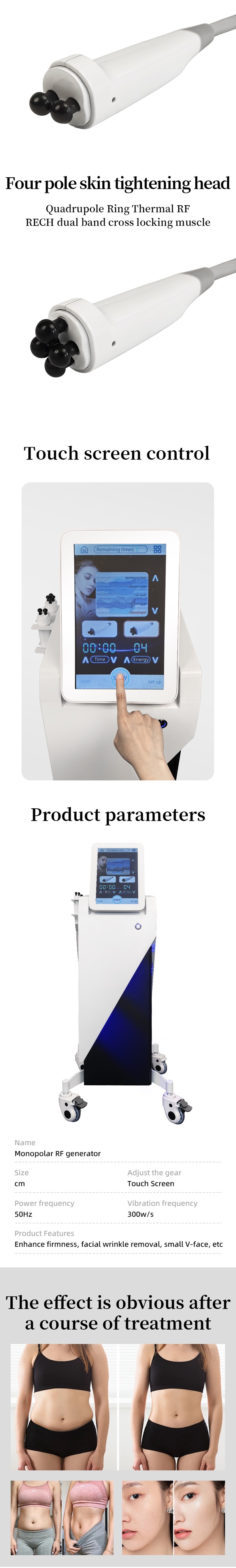

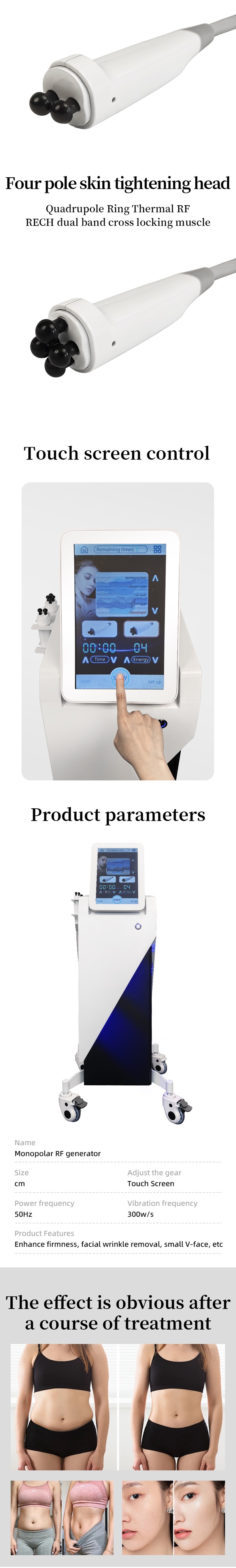

Function: free combination of RF intensity (0.5-3MHz)/microneedle depth/red light mode

Our products include: